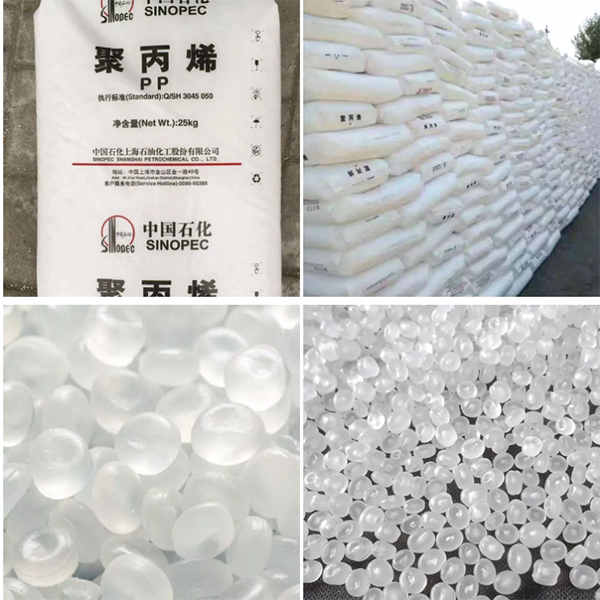

PP resini

O le Polypropylene o se resini gaosia e ala i le polymerization o le propylene (CH3—CH=CH2) ma le H2 e fai ma sui mole mole mamafa.E tolu tagata fa'alogo a le PP – isotactic, atactic ma syndiotactic.O le PP e leai ni vaega polar ma e sili ona lelei le fa'aogaina o le eletise.O lona fua fa'afefe vai e itiiti ifo i le 0.01%.PP o se semi-crystalline polymer ma lelei mautu kemisi.E mautu i le tele o vaila'au se'i vagana mea fa'ama'i malolosi.Ole inorganic acid, alkali ma vaifofo masima e toetoe lava a leai se aafiaga leaga ile PP.O le PP e lelei le vevela ma le maualalo.O lona tulaga liusuavai e tusa ma le 165 ℃.O lo'o i ai le malosi maualuga ma le maaa o luga ma le lelei o le siosiomaga fa'afefe fa'alavelave.E mafai ona tatalia 120 ℃ faifai pea.

Sinopec o le PP sili ona tele gaosi oloa i Saina, O lona PP gafatia e tusa ma le 45% o le aofaʻi o le atunuʻu.O lo'o iai i le taimi nei le 29 PP la'au a le kamupani e ala i le fa'aauau pea (e aofia ai ma i latou o lo'o fausia).O tekonolosi o lo'o fa'aogaina e nei iunite e aofia ai le fa'agasologa o le HYPOL a le Mitsui Chemical, le fa'agasologa o le kesi a Amoco, le fa'agasologa o le Spheripol ma le Spherizone a Basell ma le fa'agasologa o le kesi a le Novolen.Faatasi ai ma lona malosi suʻesuʻega faʻasaienisi gafatia, Sinopec ua tutoʻatasi atiina ae se lua-tupulaga loopprocess mo PP gaosiga.

PP Features

1. E laʻititi le vavalalata vavalalata, naʻo le 0.89-0.91, o se tasi o ituaiga sili ona mama i palasitika.

2.mea lelei faʻainisinia, faʻaopoopo i le aʻafiaga o le tetee, o isi mea faʻainisinia e sili atu nai lo le polyethylene, e lelei le faʻaogaina o le gaosiga o gaioiga.

3. O loʻo i ai le maualuga o le vevela ma o le faʻaaogaina pea o le vevela e mafai ona oʻo i le 110-120 °C.

4.mea lelei vailaʻau, toetoe lava leai se vai absorption, ma e le tali atu i le tele o vailaau.

5.le fua e mama, e le oona.

6. insulation eletise e lelei.

Fa'aoga masani mo le vasega PP

(ona o mea tau maketi ma le gaosiga o taimi, o le faʻataʻitaʻiga moni atonu e ese, faʻamolemole faʻafesoʻotaʻi matou mo faʻamaoniga faʻapitoa)

| Vaega | Vasega | MFI | Malosi | Talosaga Tele |

| Homopolymer - Extrusion | F103 | 3.3 | 0.9 | Vasega Ata Ata BOPP - Fa'amoemoega Lautele, Lamination & Metallizable ata |

| T30S | 3.3 | 0.9 | Raffia Tapes, Lalaga taga mo le afifiina o Fertilizers, Sima, Polymers, Fa'alava kapeta, FIBC etc. | |

| T103 | 3.3 | 0.9 | Ipu Thermoformed, koneteina ma isi mea e fa'aaoga | |

| F110 | 11 | 0.9 | TQ ma Fa'a Ata Ata mo Fa'aputuga Fa'apitoa ma isi. | |

| Homopolymer – Fa'asu'i tui | M103 | 3 | 0.9 | Fuafuaga Lautele Fa'asu'iina |

| M106 | 6 | 0.9 | Fuafuaga Lautele Fa'asu'iina | |

| M108 | 8 | 0.9 | Fuafuaga Lautele Fa'asu'iina | |

| M110 | 10 | 0.9 | Fuafuaga Lautele Su'i Su'i, Meafale ma isi. | |

| Impact Copolymer – Fa'asu'i Su'i | M304 | 3.5 | 0.9 | Vaega o Taavale, Pusa, Paila, Meafale ma isi. |

| M307 | 7 | 0.9 | Fuafuaga Lautele Fa'asu'iina | |

| M310 | 10 | 0.9 | Pusa maa | |

| M311T | 10 | 0.9 | Fa'apipi'i, Vaega o Ta'avale, Atopa'u ma Vaega Fa'apisinisi | |

| M312 | 12 | 0.9 | Fa'apipi'i, Vaega Fa'apisinisi, Vaega o Ta'avale, Atopa'au, Paila, Meafale, Mea Tau Lafoma ma isi. | |

| M315 | 15 | 0.9 | Fuafuaga Lautele Fa'asu'iina | |

| M325 | 25.0 | 0.9 | Fa'apipi'i, Vaega o Ta'avale, Meafale, Vaega o Mea Fa'aoga, Fa'apipi'i Fa'alava | |

| M340 | 40 | 0.9 | Mea faigaluega & Mea Pa'epa'e, Vaega Ta'avale, Fa'afefiloi,TWIM | |

| Copolymer fa'afuase'i - Blow Molding | B202S | 1.9 | 0.9 | Fagu ma Koneteina mo Oloa Fa'afoma'i ma Malamalama (eg IV Fagu Suavai) ma isi |

| B200 | 1.9 | 0.9 | Fa'amoemoega Lautele Mea Fa'ali'i & Fa'anofoa, Pepa mo Faila & Fa'amau. | |

| M212S | 12 | 0.9 | Koneteina Malamalama Maualuga, Meafale, Su'i tui, Measu'esu'e & Fagu ISBM |

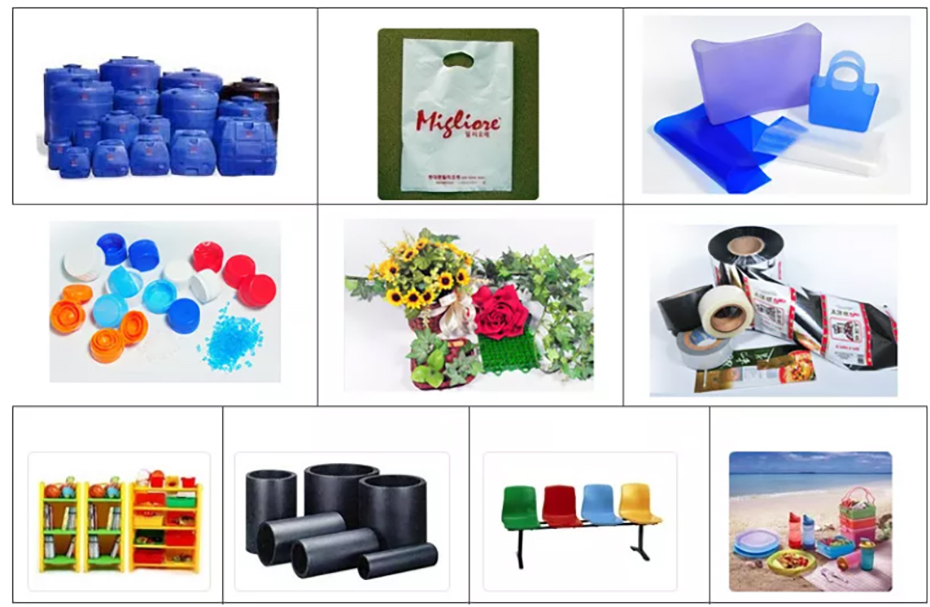

Fa'atatauga

O le PP e iai le tele o talosaga.E fetaui lelei mo le tele o metotia faʻagasologa e pei o tui tui, faʻapipiʻiina ma faʻafefeteina ma faʻaaogaina lautele i le ie, afifiina, mea eletise fale, taavale ma fale faʻatau fale.La'au Sinopec PP e iai tekinolosi eseese e maua ai le homopolymer, random copolymer ma le aafiaga copolymer PP ma mea eseese.O nei oloa e aofia ai le ata BOPP, ata CPP, fiber, paipa, faʻapipiʻi, vulu ma mea faʻapipiʻi tui.

1. Fiber (Kapeta, Ieie, Nonwoven, Upholstery, etc.)

2.Film (fa'atau taga, lafo ata tifaga, multilayer ata, ma isi)

3.Blow Molding (Fomai & Cosmetic container, Lubricant & Paint container, etc)

4. Extrusion Molding (pepa, paipa, uaea & uaea, ma isi)

5. Injection Molding ( Taavale, Fa'aeletonika, Faufale, Meafale, Meafale,

meataalo, ma isi)

afifi

I le 25kg taga, 16MT i le tasi 20fcl e aunoa ma le pallet po o le 26-28MT i le tasi 40HQ e aunoa ma pallet po o le 700kg jumbo taga, 26-28MT i le tasi 40HQ e aunoa ma pallet.